Aluminum-based electrical circuitry was first used for energy applications in the early 1900s. Use of aluminum circuitry grew rapidly after World War II and it has actually progressively changed copper as the conductor of choice in energy grids. The metal has significant cost and weight benefits over copper and is now the chosen material for electrical energy transmission and circulation usages. AA-8000 series aluminum alloy conductors have more than 40 years of reputable field installations and have been recognized specifically by the National Electrical Code for over three decades. Aluminum electrical wiring is a significantly popular choice for utilities and contractors. The market has actually grown 20 percent over the past years.

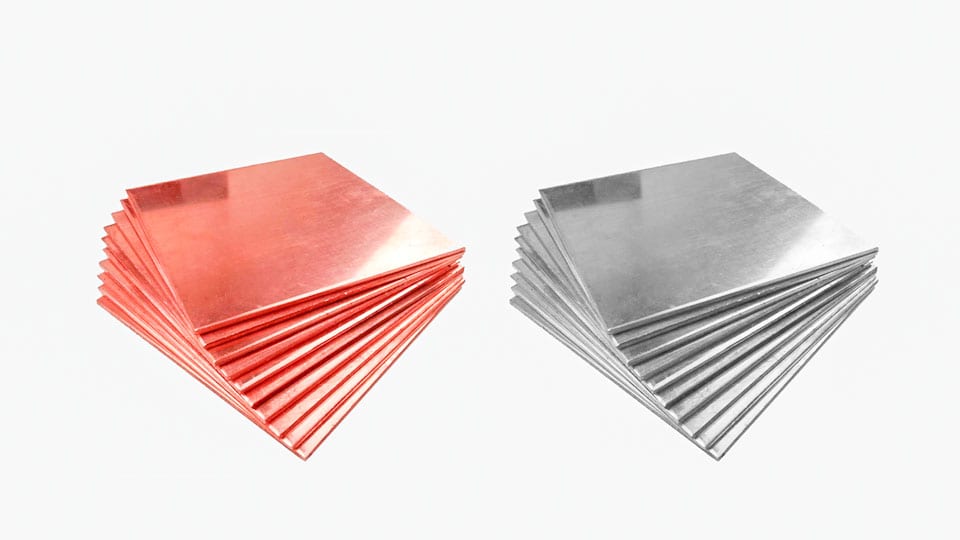

Aluminum's use in energy grid transmission and circulation networks increased quickly after World War II. The metal weighs half of the equivalent capability of copper and was advantageous for the construction steps of pulling wire, suspension and support. From there, aluminum circuitry usage spread downstream to service drops, service entrances and developing wire feeders. Aluminum has cost and weight advantages over copper and is the preferred product for electrical power transmission and distribution uses today. Due to aluminum's exceptional conductivity-to-weight ratio compared to copper, the metal is now used for electrical wiring in residences, structures, airplane and appliances.

Aluminum has likewise been adapted for use as stiff electrical avenue. (An electrical avenue is a tubing system used for protection and routing of electrical circuitry.) Unlike steel channel, rigid aluminum does not stimulate, resists deterioration and will not rust. These residential or commercial properties of aluminum are critically important for electrical applications within coal mines, grain elevators and refineries (where sparking can result in devastating results).

In 1882, Edison Electric opened the world's very first steam-powered electrical energy generating station. This station provided a number of regional customers with electrical energy for lighting. At that time, aluminum was thought about a rare-earth element and valued higher than both gold and silver. Copper, having been known to humanity for countless years, was easily offered as conductive material. For Edison's station and throughout the early development of nationwide power grids, copper was the practical option. Aluminum was first used for electrical utility applications in the early 1900s. For example, as reported in The Electrician journal, September 7, 1900: "The North-Western Elevated Railway Co. of Chicago have actually utilized 150,000 pounds. aluminum to equip their overhead track in Chicago, and the line was started with the brand-new power in the spring of this year."

When the first electrical transmission network was developed (Edison, 1882), aluminum was thought about a precious metal and better than both gold and silver. Today, aluminum is a LEED-favored material for construction and operation of high-performance green buildings. Aluminum circuitry requires minimal energy to recycle and loses none of its homes during the recycling process.

Stay Connect