Application

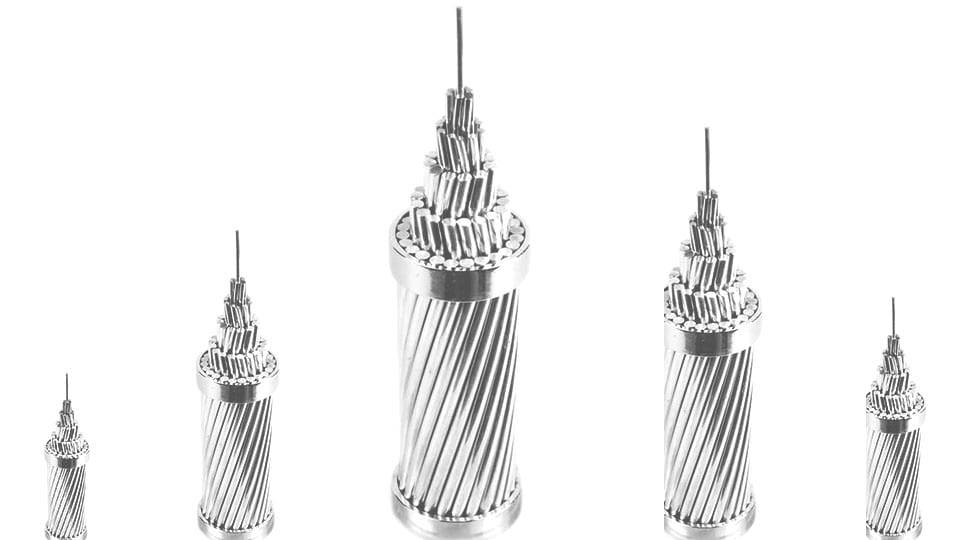

- All Aluminum Alloy Conductor (AAAC) a concentrically stranded conductor made from Aluminum-Magnesium-Silicon Alloy 6201-T81 wires, comparable in look to a 1350 grade aluminum conductor.

- AAAC conductor offer an outstanding efficiency for power transmission and circulation market as main and secondary conductor.

Product Features

- Large period and long crossing is possible. Tensile strength is 30% more than AAAC with exact same size. And much greater than All Aluminum Conductor which is particular.

- Lower tower is possible. Light in weight and much better droop particular approx 1.3-1.4 times much better than AAC.

- Better Ampacity and Overload securely along with its rust resistance. Exceptional and steady transmission under 90 ° C and as much as 150 ° C when overload.

- Excellent and detailed efficiency might conserve your expense and time in tower building, setup and upkeep.

Our Advantage.

- Proudly be confirmed by BureauVeritas, ISO, CCC, OHSAS and so on

- Free sample.

- Massive assembly line to provide your competitive cost.

- Manufacture and export AAAC because 2007.

Construction

- Concentric-lay-stranded.

- Aluminum Alloy Wires Strands: 7, 19, 37, 61, 91.

Specifications

- AAAC Products fulfill or surpasses the requirements IEC 61089 equivalent to ASTM B399, DIN 48201, BS EN50183.

- Available Code number: 16, 25, 40, 63, 100, 125, 160, 200, 250, 315, 400, 450, 500, 560, 630, 710, 800, 900, 1000, 1120, 1250.

- Grease or other unique surface readily available as you needed.

- Rare specs or producing by your sample can likewise be complete filled. Please don’t hesitate to query with our sales group.

Manufacturer Process

- As a leading rank All Aluminum Alloy Conductor (AAAC) maker, we follow rigorous global basic production procedures and have actually been validated by Bureau Veritas, we likewise pasted series of assessments consisting of CCC, ISO, OHSAS, and the majority of certificates within cable television market has actually been obtained.

- AAAC conductor manufacture circulation includes more than 30 procedures, and every primary procedure has a QC check, you are ensured with highest.

- Any third-party examination representative is invited.

Package & Shipping

- Finished AAAC conductor wire are loaded with wood/ steel reels for the benefit of your setup.

- Sealed with pieces and enhanced with steel strip for extra strength, strong enough for abroad transport.

- Reels/ Drums are repaired with wood or steel frames within shipping container.

- Drums can be steel made and size can differ with your requirements.

Stay Connect