5052 aluminum alloy is Al-Mg alloy, cold workability, good molding processability, corrosion resistance, 5052 alloy is the most widely used of a rust-proof aluminum, the strength of this alloy is high, especially with fatigue strength , Plasticity and high corrosion resistance, hardening in the semi-cold when the plastic is still good, 5052 alloy used to do without the pressure of the beverage cover, the state is H19, the first material to do the oxidation treatment to improve paint adhesion and corrosion resistance, both sides After painting in the lid forming process, I produced the 5052 alloy lid material surface quality, performance and stability.

Application

Oxidation materials, general volumes, fuel tank materials, LCD backplane, door sheet

Features

- With high plasticity, corrosion resistance, suitable for use in marine environments.

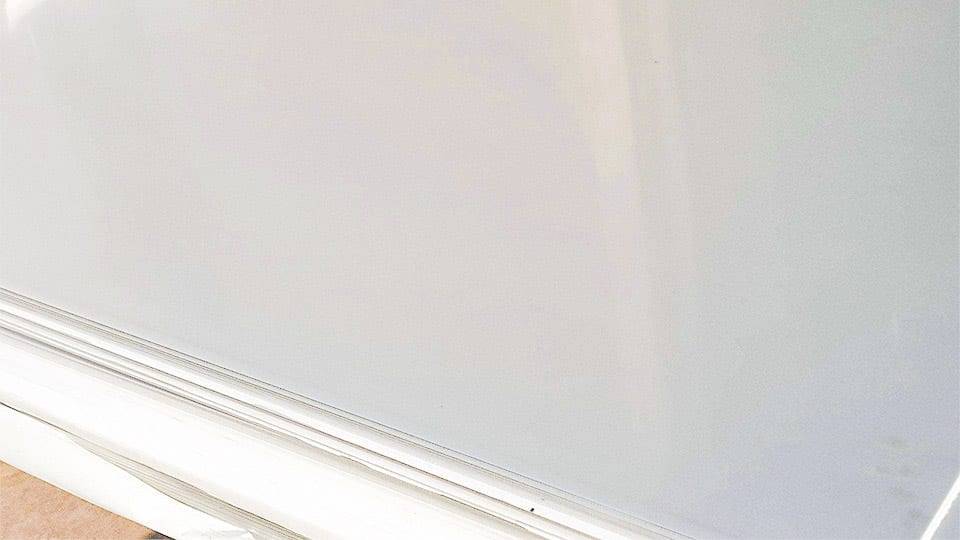

- The surface of the aluminum plate without skin, bubbles, surface roughness and local mechanical damage, aluminum surface without cracks, no corrosion spots and nitrate traces.

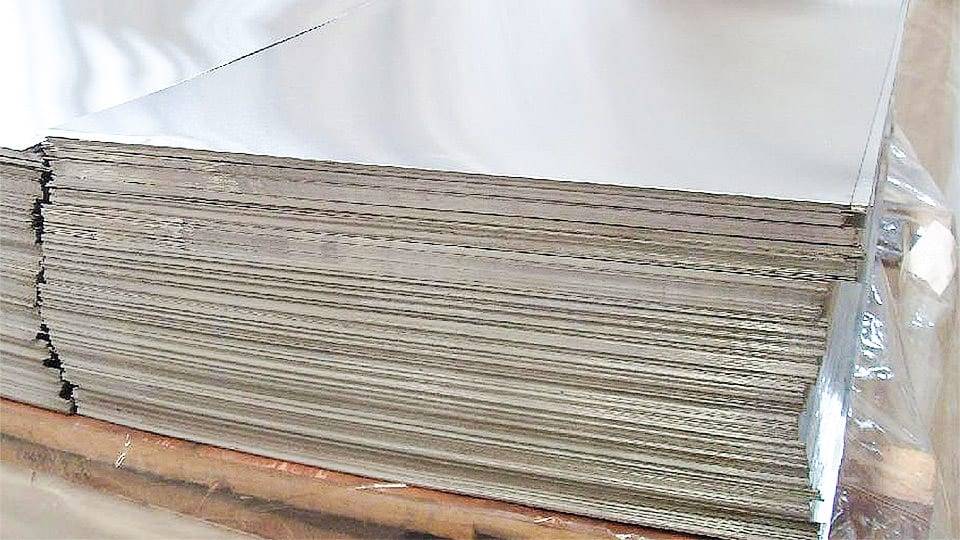

Specification

MOQ:3Ton

| Typical alloys | Material status | Thickness(mm) | Width(mm) | Length(mm) | Typical products |

| 5052 aluminum plate | O,H12,H14, H16,H18,H19, H22,H24,H26, H28,H32,H34 H36,H38,H111, H112,H114,H 116,H321 | 0.15-600 | 300-1600 | 800-6000 | Oxidation with aluminum, marine sheet metal parts, chemical oil storage devices |

Workshop

Inspection

Certificates

Stay Connect