A combination of effectiveness and flexibility makes rubber cables perfect to offer power supply to portable electrical equipment and gadgets. The mechanical stresses involved in moving device require cables to stand up to a high degree of wear-and-tear. Our HOFR (heat & oil resistant and flame-retardant) the cables are designed to hold up against severe weather condition, oil/grease, mechanical as well as thermal tensions, also using substances such as Ethylene Propylene Rubber (EPR) and Chlorosulphonated Polyethylene (CSP) as insulating products. These flexible rubber cables are suitable for a wide range of applications consisting of mobile power materials, light and sturdy devices, and submersible pumps, as welding cables providing power from the device to the tool, for audio visual equipment, and devices on building and construction sites.

Application

Heavy duty Rubble cable is tough rubber sheathed cables and rubber compound insulated cable, which is widely used for equipments when hard usage performance and complex operating environment are considered as following:

- As power cable for Drives devices, portable electrical equipments which needs to moved around on a high frequency especially for work site or construction site.

- Heavy-duty industrial applications where flexibility and durability is required.

- Heavy tools, motor and welding leads.

- Power extensions, sound equipment, portable stage lights, marine dockside power and mining applications.

- Used in Water, oil or cold environment / refrigerating installations.

- Other portable, indoor or outdoor usage circumstances.

Product Features

- UV, Sunlight and Ozone resistant

- Anti-abrasive, ageing-resistant

- Excellent insulation performance as well as Physical and Mechanical Properties

- Suitable for both indoor and outdoor use

- Useful in wide range of industrial applications

Our Advantage

- Proudly be verified by BureauVeritas, ISO, CCC, OHSAS etc.

- Massive production offer you competitive price.

- Free sample and OEM.

Standards

Rubber Cable meets or exceeds the following specifications:

- H07RN-F Heavy duty chloroprene sheathed cable

- IEC 60245 Rubber insulated cables - Rated voltages up to and including 450/750 V

- IEC 60332 Tests on electric and optical fibre cables under fire conditions

- IEC 60364 Low-voltage electrical installations

- VDE 0100 Part 520 Erection of low voltage installations

Part 5: Selection and erection of electrical equipment - Chapter 52: Wiring systems - BS EN 50525 Electric cables. Low voltage energy cables of rated voltages up to and including 450/750 V (U0/U)

- BS EN 50565 Electric cables. Guide to use for cables with a rated voltage not exceeding 450/750 V (U0/U).

- BS EN 60811 Electric and optical fibre cables. Test methods for non-metallic materials . Physical tests.

Construction

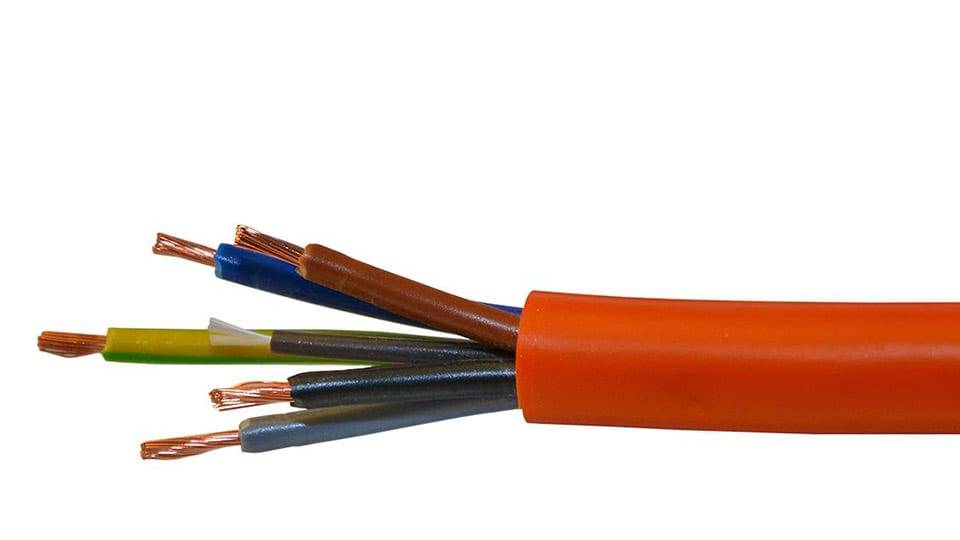

- Conductor: plain or tinned copper wires as per IEC 60228 for class 5

- Insulation: Rubber compound of Type IE4 according to IEC

- Sheath

- For single-core cables

- sheath in a single layer, rubber compound of type SE4

- For multicore cables

- Cross-sections not exceeding 10 mm2 - in a single layer, rubber compound of type SE4

- Cross-sections in excess of 10 mm2

- either in a single layer, rubber compound of type SE4

- or in two layers, with the inner layer made of rubber compound of type SE3 and the outer layer of rubber compound of type SE4

- For single-core cables

Specifications

- Cores: 1, 2, 3, 4, 5, 5&Above

- Insulation: rubber compound of type SE4

- Sheath: rubber compound of type SE4 or SE3 jacket

- Rare specifications or producing by your sample can also be full filled. Please feel free to query with our sales team.

Please contact for fast quotation or stock status check, our service team is standby for instant response.

Stay Connect