The Temper System

In addition to that huge variety of alloys grades that are available, the temper (or hardness) of each alloy can create considerable differences in their characteristics and how they react to various fabrication processes such as punching, forming, thermal cutting, welding, etc. Within the basic series categories identified in aluminum grades, there are two distinctly different varieties – Heat Treatable and Non-Heat Treatable. The 1xxx, 3xxx, and 5xxx series are non-heat treatable (they are strain hardenable only). The 2xxx, 6xxx, and 7xxx are heat treatable. The 4xxx series alloys contain both heat treatable and non-heat treatable varieties.

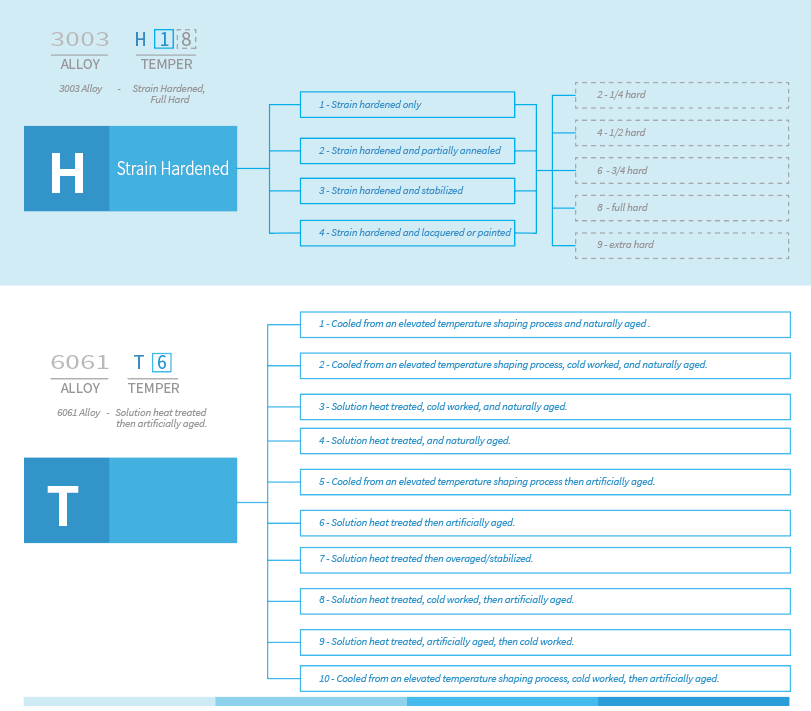

The non-heat treatable alloys acquire their optimum mechanical properties through Strain Hardening. Strain hardening is the method of increasing strength through the application of cold working. The Temper Designation System addresses the material conditions called tempers. The Temper Designation System is an extension of the alloy numbering system and consists of a series of letters and numbers which follow the alloy designation number and are connected by a hyphen. Examples: 6061-T6, 6063-T4, 5052-H32, 5083-H112.

The heat treatable alloys acquire their optimum mechanical properties through a process of thermal treatment, the most common thermal treatments being Solution Heat Treatment and Artificial Aging. Solution Heat Treatment is the process of heating the alloy to an elevated temperature (around 990 Deg. F) in order to put the alloying elements or compounds into solution. This is followed by quenching, usually in water, to produce a supersaturated solution at room temperature. Solution heat treatment is usually followed by aging. Aging is the precipitation of a portion of the elements or compounds from a supersaturated solution in order to yield desirable properties. The aging process is divided into two types: aging at room temperature, which is termed natural aging, and aging at elevated temperatures termed artificial aging. Artificial aging temperatures are typically about 320 Deg. F. Many heat treatable aluminum alloys are used for welding fabrication in their solution heat treated and artificially aged condition.

Temper Designation

Aluminum products with specific properties and product forms are identified by specifying both an Alloy and a Temper. There are 5 tempers totally defined by standards document, which are F, O, W, H, T.

- F - As fabricated

- O - Annealed

- W - Solution heat-treated

- H - Strain Hardened

- T - Heat treated

There are 2 Tempers, which are H and T are things we should pay attention to.

Stay Connect